- HKD’s partners

- Products list

- Technical Solutions

Current position: Home > Products & Service > Products list

Typical equipment disassembly, maintenance operation exercise VR products--EDOSS

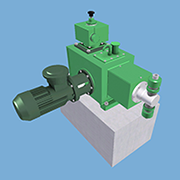

EDOSS provides an interactive 3D virtual reality environment to introduce, demonstrate, and operate the complex mechanical equipments. Trainees can easy to learn structure, working principle, and disassembly procedures. EDOSS can achieve online learning, practicing and examining functions.

System advantage:

- Interactivity:to provide a 3D interaction environment for users to do interaction via mouse and keyboard.

- High real-time:EDOSS has the optimization algorithms which can reduce the occupation of computer resources to ensure the 3D scene models operation and rendering in real-time.

- Rich 3D scene elements:There are rich 3D models library about necessary rigid object elements in EDOSS. In addition, the 3D model of the components inside the device can be developed via VESSA, and the working principle of device can be demonstrated and rendering in EDOSS.

- Role participation:Using the interactive method, EDOSS can automatically decide if the equipment could be installed while the wrong component was selected.

- High authenticity: The products in EDOSS were developed in strict accordance with the equipment design principle, mechanical structure, and operation procedure that issued by authority.

software function:

- Demonstrate equipment working principle;

- Internal and external structure of equipment;

- Simulate equipment disassembly process;

- Independent exercise and evaluation function.

Products:

|  |  |  |  |

| Silicone oil furnace | Lift check valve | Expander | Shielding pump | Swingcheckvalve |

|  |  |  |  |

| Molecularsieve tower | Debutanizer | ButterflySwingCheckValve | Filter | Orbit ball valve |

節(jié)閥.png) |  |  | 式安全閥.png) |  |

| Pneumatic control valve | Spring safety valve | Reboiler | Pilot operated safety valve | Ball valve |

|  |  |  |  |

| Plunger pump | Block valve | Gate valve | Three-phase drum | Butterfly valve |